Postwar Prosperity

Postwar prosperity caught the Northwest by surprise. As war industries demobilized, business pundits predicted a depression like the one that had followed World War I, accompanied by labor troubles and civil unrest. For a while it looked as if the doomsayers might be right. There was a sharp decline in business activity in May 1945, and by summer’s end defense plants were laying off thousands of workers. In addition, many workers who had migrated to Oregon to take wartime jobs decided to stay, contributing to a large pool of workers and a lasting population increase.

Nevertheless, employment rebounded in 1946, and jobs stayed plentiful through the 1950s. Along the coast and inland, Oregon’s timber business was thriving. Big players with outside connections, like Weyerhaeuser, Menasha, Evans Products, and Georgia-Pacific, and smaller, regionally based companies like Bohemia, Willamette Industries, Boise Cascade, and Roseburg Forest Products dominated the industry. The brisk California market for framing lumber opened a niche for local gyppo (that is, small independent) operations, too. Expanding markets and larger profits prompted the larger operators to invest in modern milling technology and to expand their product line to include plywood and particleboard.

Plywood was in high demand both during and after the war. More than seventy plywood plants opened their doors in Oregon between 1940 and 1960, including plants in Astoria, Garibaldi, Tillamook, Gardiner, Reedsport, North Bend, Coos Bay, Coquille, Port Orford, Gold Beach, and Brookings. Particleboard, a four-by-eight-foot pancake of pressed planer shavings and sawdust held together by glue, was a new product that used materials once burned as waste. Cheaper than plywood, it sold well as underlayment for floors and inner cores for solid-core doors or, with the addition of decorative veneer, as cabinet or furniture stock.

Wood chips, another waste material, found a growing market in pulp and paper manufacturing. As companies stretched their raw material, making profit from what had earlier been discarded, the once-ubiquitous wigwam burners began to disappear from the landscape. The air around mill towns became noticeably cleaner.

Timber supply became a worry in the late 1950s and into the 1960s. Private companies were chewing through their own timber fast, and federal forests increasingly stepped in to fill the gap. Between 1957 and 1965, the harvest of federal timber in Oregon more than doubled, from about 2.3 to 5 billion board feet, while the private timber harvest declined by almost the same amount, from 7 billion to about 4.4 billion board feet. Managers of federal forests were shifting from a mostly custodial role to an active participation in the region's timber economy, a development that would have repercussions two and three decades later as people began to worry about the environmental impact of logging.

The postwar building boom produced a species of economic life in timber towns along the Oregon Coast—the chewing-gum-and-baling-wire operation known as the gyppo. As defined in a glossary of forestry terms, a gyppo is an “independent logger who usually runs small-scale logging operation.” It is not clear how “gyppo,” an epithet connoting a swindler or a cheat, came to be applied to these shoestring operators, who were undoubtedly as honest as anyone else in the business at the time.

However they got their name, gyppos working the coastal timber country after World War II were run by hardworking, undercapitalized, mechanically ingenious operators, sometimes single men or husband-and-wife entrepreneurs with a few employees, sometimes small partnerships, often whole families. Women worked on gyppo operations and in the lumber industry throughout the twentieth century, many as cooks and kitchen help in logging camps. During the 1940s, women held approximately one-third of the jobs in mills.

The gyppos were an important component of the postwar lumber economy along the coast between 1946 and 1960. They typically furnished logs or rough-cut lumber to larger mills, which then made finished lumber for the California housing market or markets elsewhere. It was not an easy way to make a living. Gyppo loggers typically could not afford the heavy yarders and other equipment used by larger companies, so they bid on close-in tracts of second-growth timber that could be logged with a tractor and a winch or an old wood-fired donkey engine. A gyppo sawmill was typically a temporary, portable affair thrown up on a wooded hillside and powered by a gasoline engine pulling a cat’s-cradle of belts.

The gyppo’s heyday ended when lumber fever cooled down in the late 1950s. Logging and milling became more competitive, more technologically demanding, and more hedged about with regulations. Some gyppos survived to take their place among the bigger operations, but most such operations died out. Their memory lives on in the romantic figure of the rough-hewn logger in novelist Ken Kesey’s Sometimes a Great Notion. Hank Stamper sometimes is evoked in a modern-day nostalgia for a simpler era, for a time when the Stamper family motto, “Never Give An Inch,” was a full-throated battle cry.

© Gail Wells, 2006. Updated and revised by OHP staff, 2014.

Sections

Related Historical Records

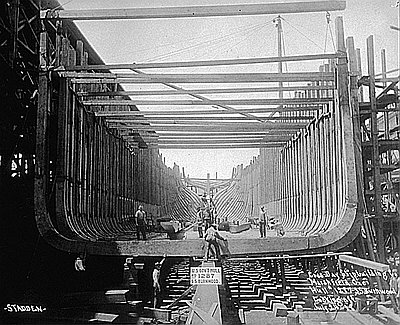

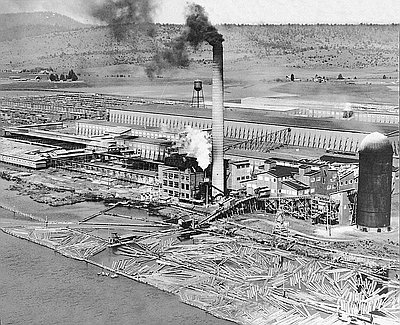

Weyerhaeuser Timber Company

At the time of this photo in 1941, Weyerhaeuser Klamath Falls employed approximately 1,200 men and produced 200 million feet of wood products each year. Weyerhaeuser experienced a …

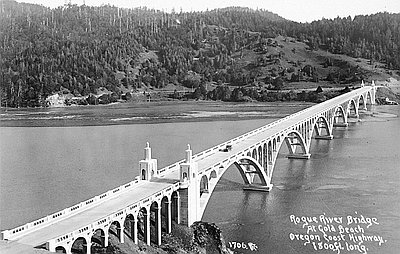

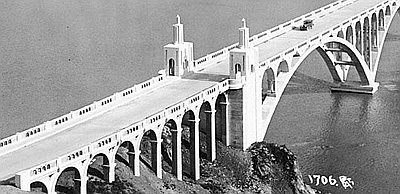

Rogue River Bridge, Gold Beach

The Isaac Lee Patterson Bridge across the Rogue River on Highway 101 at Gold Beach is depicted above at the time of its completion in 1931; it was …